Rock Wool Production Lines

.png)

Rock wool production lines: machinery for insulation

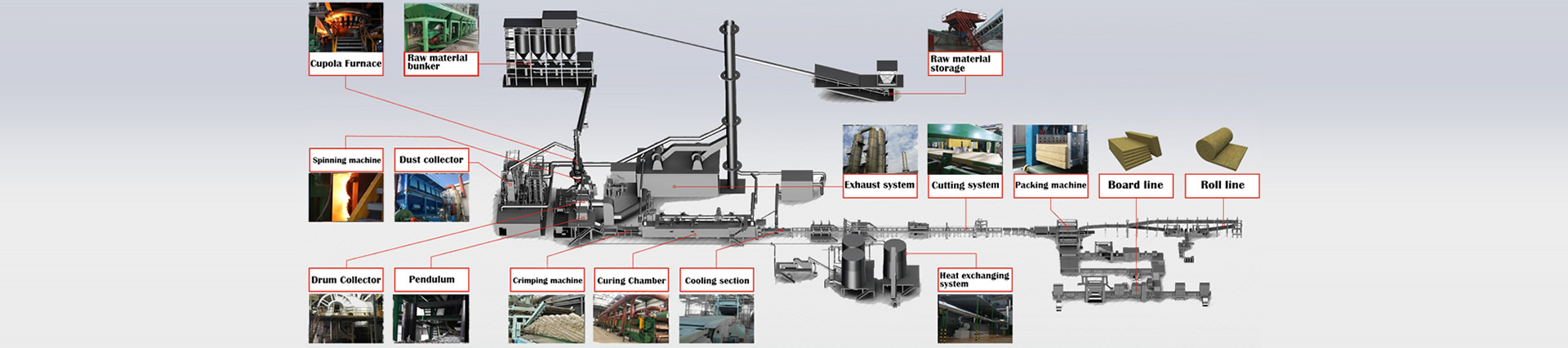

A complete rock wool production line consists of several machines that process the material, from melting to packaging.

The “hot” part is located at the beginning of the line where the machines melt the raw material and transform it into fiber, followed by the polymerization and processing of the fiber, when the product acquires the final shape (rigid boards, stitched mattresses or felts). The packaging system is located at the end of the line and consists of machines that package the product and prepare it for warehousing or shipment.

Rock wool: features of production lines

Indicative production capacity: 200 Kg/hr to 8 t/h (finished product)

Type of melting furnace: Cupola furnace (for all capacities) or Horizontal Furnace and electric oven (for small and medium lines).

Nominal line width: from 1,200 to 2,400 mm

Type of finished product:

• Felts

• Boards

• Stitched mattresses

Product features:

• Density 30 – 200 kg / m3

• Thickness 30 – 200 mm

• Width 400 – 2400 mm

All rock wool products can be coupled with different types of materials (depending on their use) such as paper, aluminum, glass veil.