Waste rock wool fiber briquette production line

Main technical features:

|

1. Forming machine frame: Made of high-strength steel and special welding process, it is extremely strong. |

|

2. Realize the automation of the whole block production line, save the operation time and improve the production efficiency. |

|

3. One machine is multi-purpose, changing the mold can produce different specifications of briquette (cylinder, hexagonal, cube, etc.) |

|

4. The control system has a self-locking function to avoid malfunction. Remote fault diagnosis can be realized through telephone connection to ensure the smooth progress of customer production in real time. |

|

5. Die pressing head: electromechanical and hydraulic synchronous drive, the height error of the same pallet product is very small, and the product consistency is good. |

|

6. Arch-type fast laying device (especially beneficial and more uniform for briquette.) |

Production raw material: fly ash, waste rock wool, cement, etc.

Main technical parameters:

|

Molding period |

15(s) |

Block production line power |

50(kw) |

|

Forming method |

Vibration compression molding |

Shock force |

60-100(KN) |

|

Machinery weight |

5000(kg) |

Vibration frequency |

3800-4500 (times/min) |

|

Pallet specifications |

880×550×20(mm) |

External specifications |

22×6×3(m) |

|

Rated pressure |

31.5(mpa) |

Device operating temperature |

0-50 degrees |

Output:

|

Unit description |

Specification |

per plate |

Daily output (8 hours) |

Briquette capacity(8 hours) |

|

Cylinder/hexagonal column |

Diameter 120mm, Height 120mm |

28 |

640-800 Plate |

80-120 Ton |

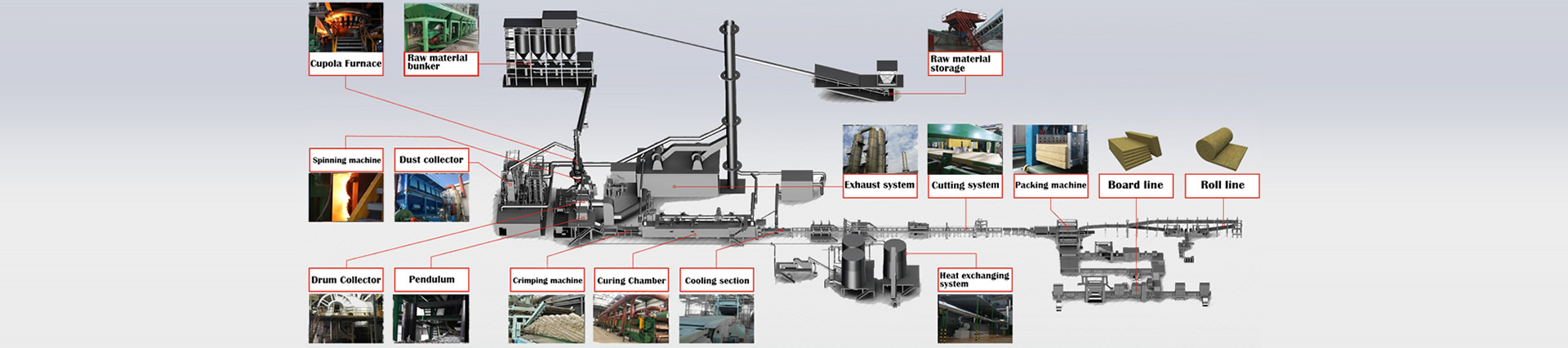

Production line process:

No need to use gas or diesel, just electricity

A total of 3 workers are required (1 worker manages the entire production line, 1 worker drives tractor shovel, 1 worker drive forklift), if use bag cement, 1 more worker required for adding the cement.

The waste fiber briquette only needs to use conventional 425# cement as a binder, no additional binder is required, and the cement ratio is 8%-10%, Ash could be rejected and undersized(less than 2cm) basalt, dolomite, lava residue, coke, etc.

The use of waste briquette will not affect the performance of the furnace, and could save the amount of normal raw material. The briquette mixing ratio should be less than 20% of total amount of raw material.

Installation in China about 1 week, 1 engineer technical service at site, local factory arrange 4-5 workers supporting. Cost of technical service will be charged separately.

Other

Price offer in attachment(not including cement tank).

Cement tank(Buyer scope) shown in red square as below

.png)