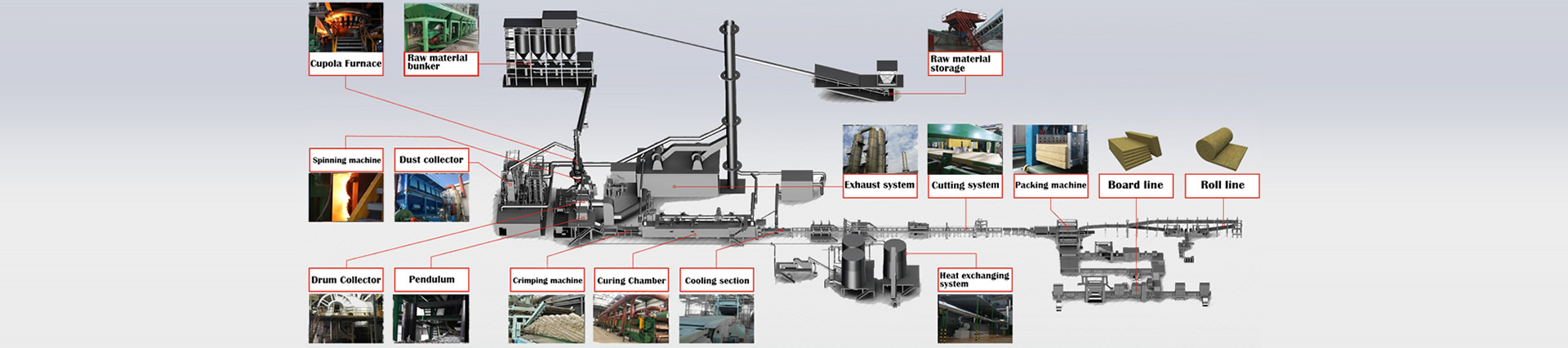

New technology of rock wool production line

Feeding system

The raw material silo is automatically unloaded, and the raw materials can be weighed with high precision. The blanking mechanism has been specially designed to achieve high-precision uniform blanking and precisely match any formula.

Melting system

Customizable melting system, matching manufacturing according to customer's required output. We can also customize the blower fan and spinning machine power according to the required production capacity and local voltage to adjust the fiber length.

Various options of spinning machines, from traditional open type to the latest Direct Drive type. With the most advanced center-spraying four-roller fiber-forming large-capacity spinning machine high quality rock wool product can be made to ensure the competitiveness in the high-end market.

Collector and pendulum system

The drum-type wool collector has a higher speed than the traditional triangle screen type and can adapt to higher production capacity. The improved design of the pendulum can achieve uniform wool for each layer and has automatic cleaning ability, which minimizes the failure rate.

Curing oven

The use of a high-standard four-wind zone curing furnace enables more precise temperature zone control than the three-wind zone, making the physical properties of rock wool products more outstanding.

High-efficiency recycling system

The scrap generated in the production process can be transported back to the forming chamber through multiple ways, maximizing the output and increasing the utilization rate of raw materials. Heat energy is transferred between incinerators, cupolas and curing oven to form an energy cycle, which can save a lot of natural gas and coking coal.

.jpg)

Cutting system

High-precision cutting system, there is almost no error in longitudinal cutting, and the diagonal error in transverse cutting is within 2mm. The independent backup system design can ensure days of uninterrupted continuous work and minimize downtime.

.jpg)

Packing system

The fully automated packaging system can be customized to save manpower and enable flexible packaging sizes and styles.

.jpg)