What is ROCK WOOL and how it is make

Rockwool (stone wool or mineral wool) is a non-metallic, inorganic, fibrous, glossy substance made from stone / rock (volcanic rock, typically basalt) and blast furnace slag as the major components.

Rock wool is mainly used as an insulation material to save energy, combat noise, reduce the risk of fire and to protect the property and life in the event of fire. Rockwool panels are widely used in the construction industry all over the world.

Rock wool is an excellent and cost-effective material for thermal, electrical & acoustic insulation. It has gained extensive popularity for its properties in fire-resistance, thermal insulation efficiency, durability, ease of installation & sound adsorption.

Common house-hold applications of rock wool include insulation of lofts, cavity walls, internal & external walls, flat roofs & heating systems. Common industrial applications include large diameter pipe insulation, insulation of tanks & vessels, insulation for boilers, turbines, ovens & critical marine & offshore installations, including fire & acoustic insulation in ships and in oil rigs.

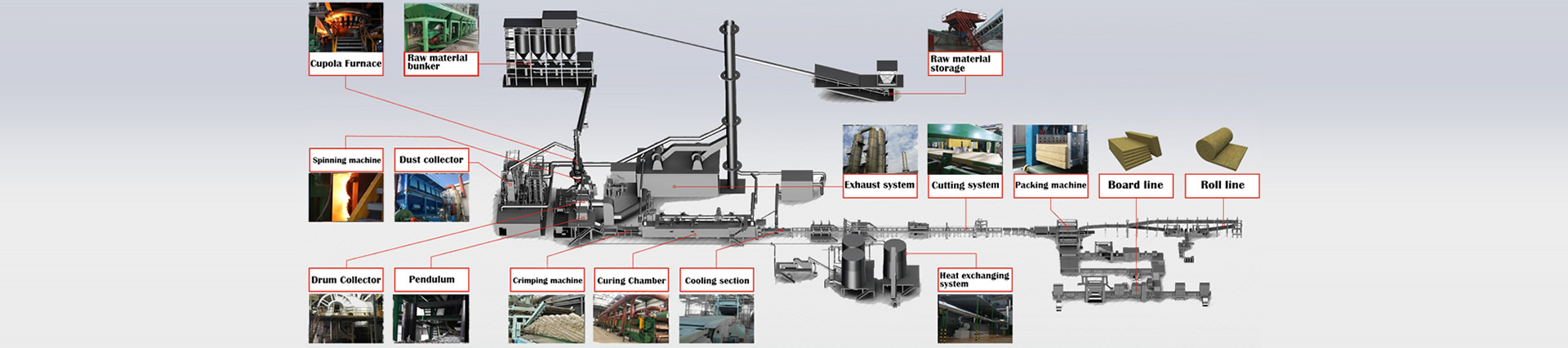

Traditionally for rock wool manufacture, ingredients like basalt stone, blast furnace slag, limestone & dolomite are melted in a cupola furnace, using coke. The molten lava is poured into a high speed centrifugal machine, which converts the same into fibers. These fibers are collected by a drum type wool collecting machine & subsequently formed into layers by a pendulum machine & pre-pressed by a crimping machine. The boards are finally dried in a curing oven, with phenol formaldehyde glue already applied on them. The cured boards are cut into pieces, packed & sold as they are, or sandwiched in between corrugated steel sheets & then sold.