Fast Wire Contour Cutter

.png)

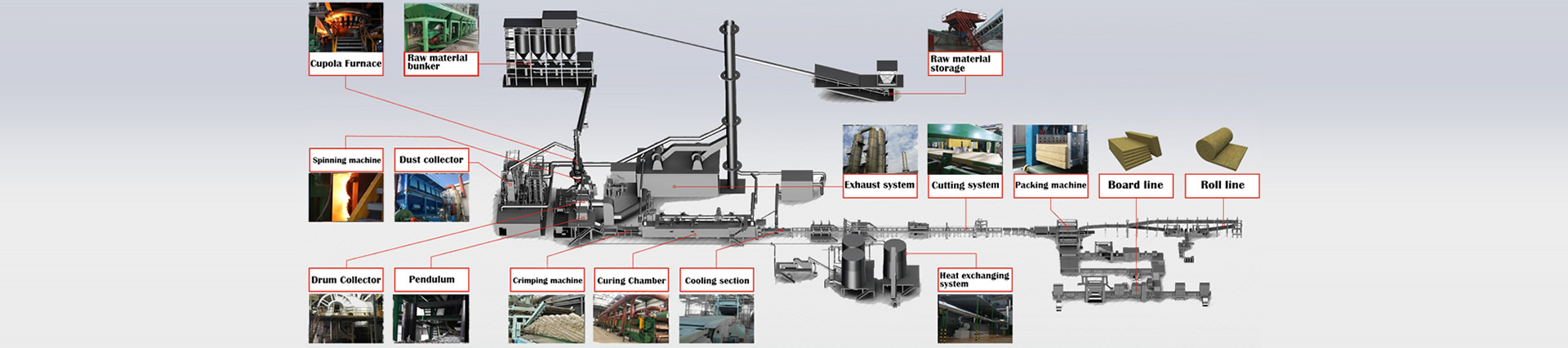

Contour cutter is a kind of programmed-control cutting machine, and it controls by computer. Through our engineer research it can complete contact with AutoCAD, it make operator easy to operate. You only need to draw the drawing of the product on the computer, and then it will work automatic by computer. It is suitable for make 2D or 3D special sponge product, EPS product or PU foam product, such as sponge pillow、EPS words、sofa etc.

Main Features of D&T Contour Cutter:

1.Big cost savings by eliminating the need to make, repair and store templates;

2.Integrated design & cutting program. Just design then cut;

3.Big cost savings by automatic arrange the product;

4.Support numeric instrument;

5.Higher material utilization resulting from computer aided nesting of shapes;

6.Cut speed can be set to arrive the best-cut speed for different foam;

7.Can pre-cut on the computer to check cutting course;

8.Several way to keep the operator safe.

.jpg)

Foam comes in many forms: flexible polyurethane for furniture, polystyrene foam for building and display products, and a wide range of rigid foams for insulation and packaging uses.

Different foams present varied challenges, and so D&T has developed a range of cutting systems, including a Fast wire contour cutting machine for rigid foams, an oscillating blade machine for flexible foams, and a multiple hot-wire machine for expanded polystyrene foam.

Fast Wire Contour Cutter is abrasive wire with a high speed. Under the high-speed the material will be grind to powder and absorbed dust blower. The computer controls the Conveyor Belt and Cutting Roller to run as what you draw on the CAD.

Main Function of the High-speed Abrasive wire machine

-Fast Cutting Speed

The new design machine cutting speed can reach 10m/min.

-Better Precision

The new machine mechanical tolerance is ±0.1mm and final product tolerance is ±0.5mm even under the high speed.

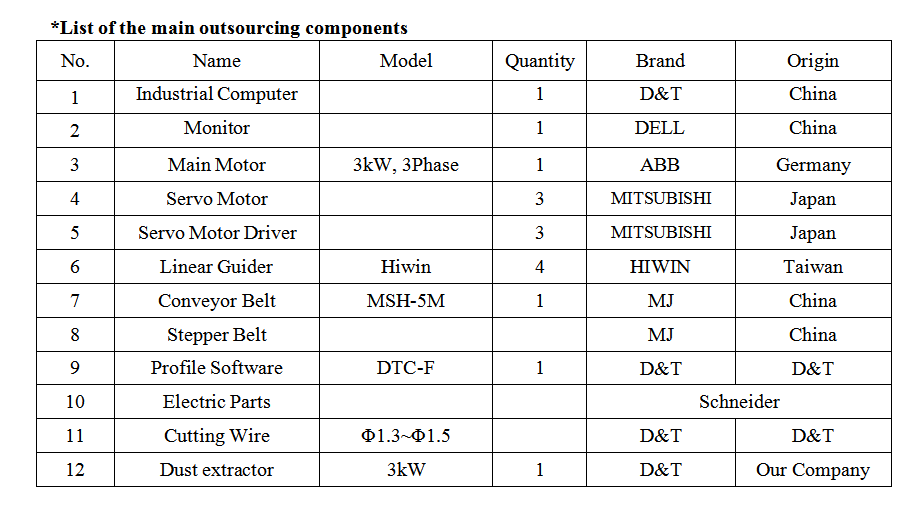

-High Quality Components

(1).jpg)

1).Servo motors and drives for X and Y axis to keep the X and Y have effective Power supplier with high performance and speed.

2).High quality reduction gears to keep the movement with enough power and still keep movement with high precision.

3).High quality gear system for X axis movement to make the X axis move with long distance with high precision.

4).Ball screw for Y axis movement to keep the Y axis with high precision.

5).High quality coupling is used to connect the stepper motor and ball Screw.

6) Soft connect the motor and wheel to avoid the motor sharking.

7).ABB motor is used for wheel run.

8).Whole moving frame made by profile aluminum to make the frame stronger and lighter.

-Perfect software makes the operate easy

The operator just input your product drawing to company by CAD. Our powerful software will translate the DXF/DWG file to standard G code automatic.

-Motion control card based on the development of CNC machining software is simple and intuitive;

-Parameter settings window is humanized, can set its own processing speed, acceleration and other operations processing conditions, so efficiency is improved greatly and adjustable control can be achieved;

-Reasonably compact mechanical structure, imported electronic inverter control of motors and precision straight linear guide

-Effective vacuum de-dust system

Most of the dust will be sucked into the dust bag by power vacuum system.

-Remove control makes the worker easy to run our machine.

.png)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)