Sustainability of Mineral Wool-Energy in Manufacture and Energy in Use

Energy in Manufacture and Energy in Use

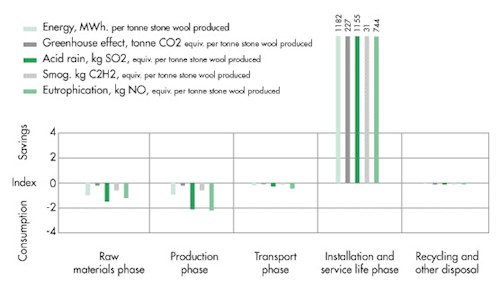

Finished mineral wool products save far more energy in use than is expended in their manufacture. The ratio of in-use savings to manufacturing emissions of carbon dioxide, the main greenhouse gas, is equally positive. Other greatly reduced air pollutant emissions include SO2, various nitrogen oxides (NOX) and fine particulates.

When mineral wool is assessed under rigorous life cycle analysis, it is found to have lower embodied energy than most non-mineral wool products, especially in applications where low density mineral wool products are used.

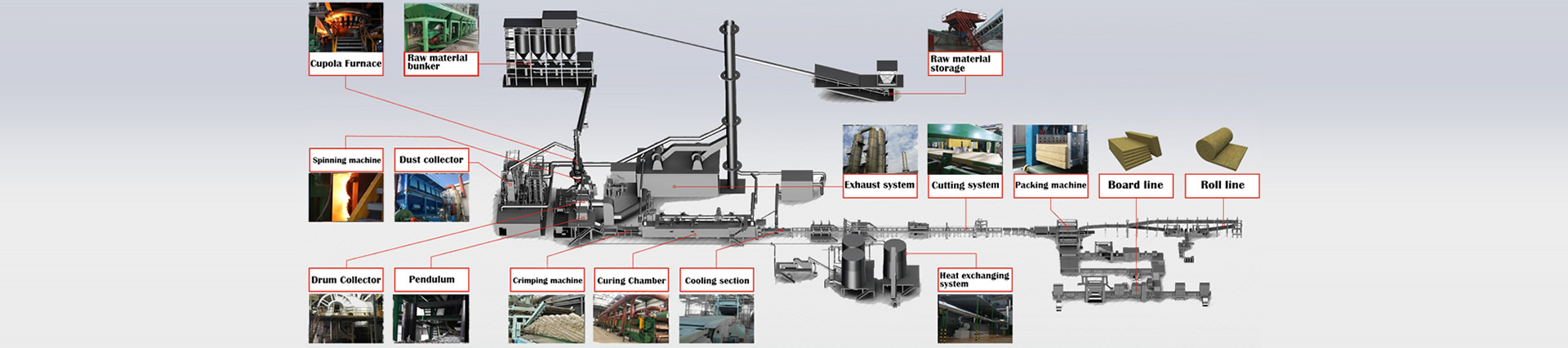

Recycling and the Manufacturing Process

Increasing amounts of recycled materials are used in the manufacture of mineral wool products.

Within the mineral wool insulation sector, a major contributor to energy savings in recent years has been the use of recycled materials in the production process. Depending on the quality and availability of local supplies, recycled content now makes up 30% to 60% of the raw material input in mineral wool production, as defined by the WRAP Rules of Thumb Guide. In some plants the recycled content is as high as 80%.

Owing to improving technology, most of the waste products are recycled back into the production process as well as increasingly using waste from building sites or demolition works to replace raw materials.

Water Pollution and the Manufacturing Process

Water used in the manufacturing process is generally in a closed circuit system. This has the twofold advantage of reducing fresh water consumption and avoiding the discharge of dirty or polluted water.

Transport of Mineral Wool Products

Modern packaging technology and the elasticity of modern mineral wool means that the products can often be packed at one ninth of their original volume without negatively affecting the installed thickness. Fewer lorries are required for transportation, thus reducing the environmental impact of transportation. Once unpacked, the product quickly expands back to its original thickness ready for installation.

Life Cycle of Mineral Wool Insulation

Diagram shows the typical environmental impact of a mineral wool product over its lifetime in terms of energy use and greenhouse gas emissions. It can be seen that the life cycle approach reveals the tremendous environmental benefits of mineral wool.